Professional Mining Lamps: Discover Our Ideal Products

24 de July de 2025

Workplace Safety in Mining: How Lighting Can Help

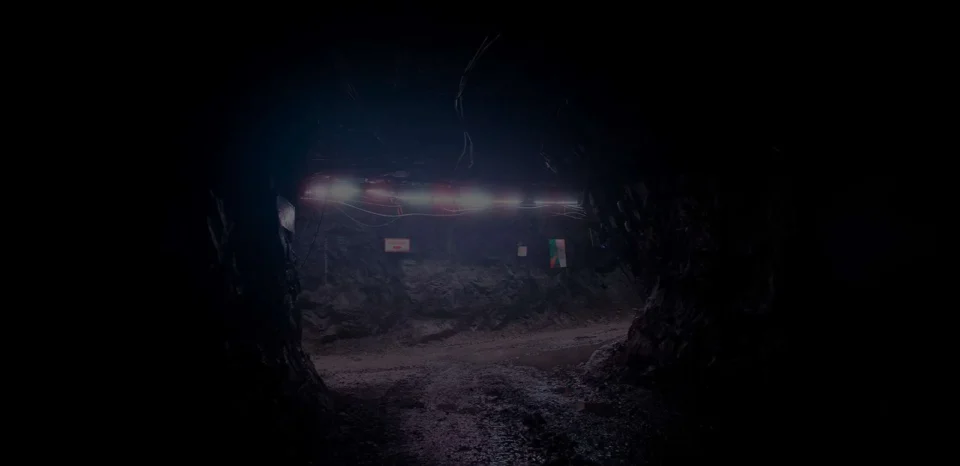

According to the OIT, the International Labour Organization, the mining sector is the most dangerous in the world to work in. The risk of accidents in mines is high, making it important to implement safety measures to ensure worker protection and improve productivity.

For this purpose, lighting is a key element. Often, the darkness in mines creates risks such as difficulty seeing workers and machinery, or even being unable to determine water depth on the ground.

Therefore, a well-lit environment increases efficiency and workplace safety in mining. With this in mind, we’ve identified some critical areas that are directly impacted by lighting equipment. We gathered this information based on our technical visits to several Brazilian mining operations. Check them out:

1. Use of Cable-Powered Floodlights

Mine lighting is typically provided by large floodlights. Such equipment is often powered by electrical cables, which can cause both safety and productivity issues.

One of the main problems is mobility, which is hindered by the weight of the devices and the cable dependency itself. Additionally, the wires also risk breaking, halting operations, or causing employees to trip.

Another issue with this type of equipment is contact with water on mine floors. Thus, no matter how resistant the cable may be, there is always a chance of rupture, which can create risks when in contact with moisture.

2. Inadequate Signaling

A crucial aspect of workplace safety in mining is signaling. Also done with lights, it is essential for controlling traffic in mines, assisting with vehicle entry and exit.

However, some equipment used does not provide sufficient illumination for good visibility of the environment and surrounding machinery. Furthermore, many beacon-type lights attached to vehicles interfere with radio waves inside mines, disrupting the internal communication system.

3. Scaling

Perhaps the riskiest task in mining, scaling is essential for verifying mine safety. However, since it is done manually and with poor lighting, the chances of accidents are high.

In general, the mining sector presents greater risk than other areas, but it is possible to take measures to ensure better protection. Having quality industrial lighting equipment is one of them, reducing a large portion of safety issues and improving business productivity.